ANSSEN Online automatic rebar counting and separation system

Product Details:

ANSSEN Online automatic rebar counting and separation system Price And Quantity

- 1 USD ($)/Unit

- 1 Piece

- 1.00 - 1.00 USD ($)/Unit

Product Description

Product Introduction

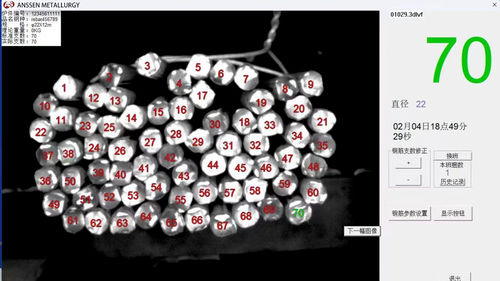

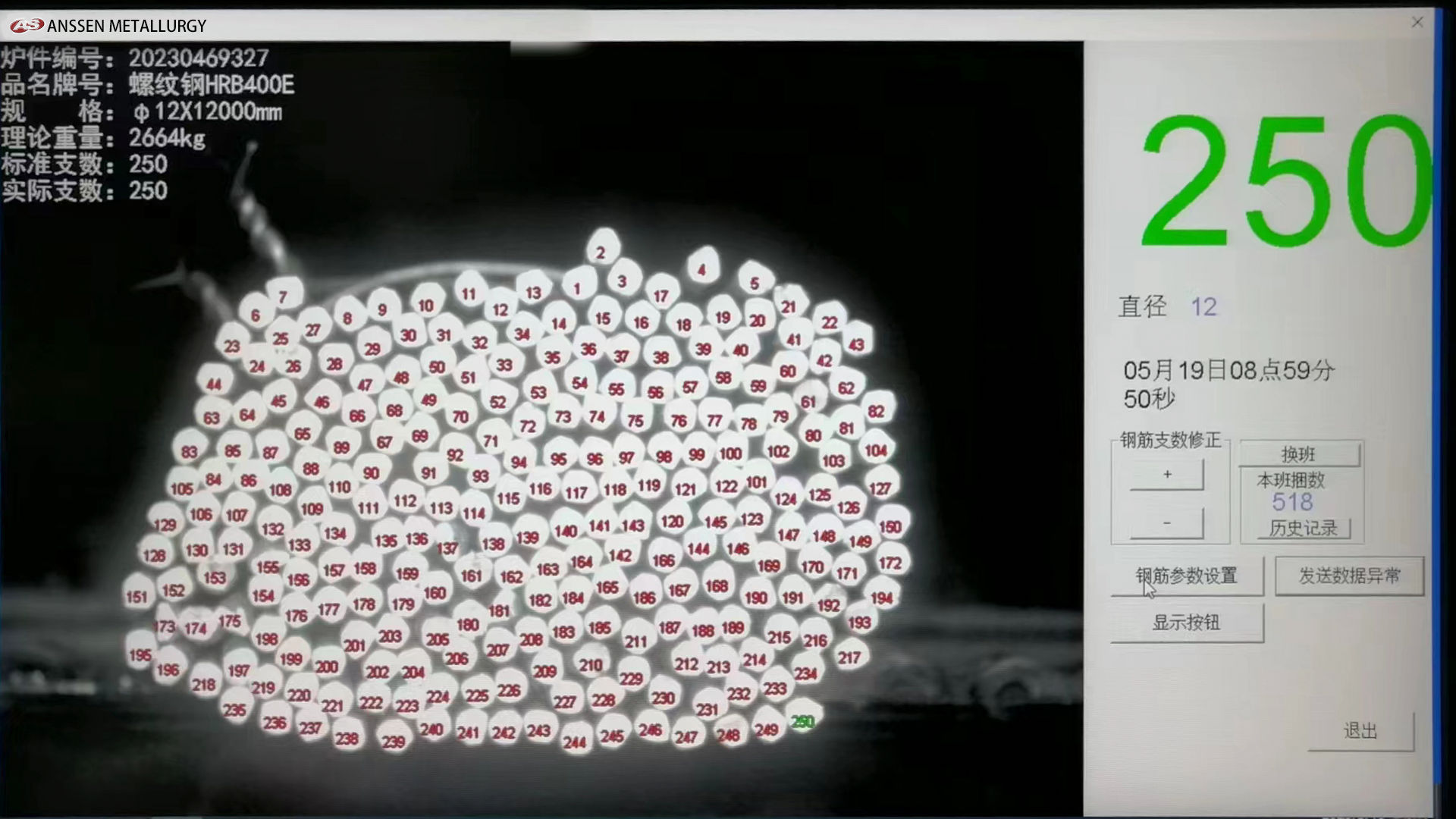

The whole bundle steel bar counter is an efficient tooldesigned specifically for the steel industry. It uses advanced imagerecognition technology to achieve fast and accurate counting of the number ofwhole bundles of steel bars. This equipment can significantly improve the workefficiency of steel mills, reduce errors and time consumption caused by manualcounting.

The fast and accurate technology of steel reinforcement cannot only improve the production capacity of steel enterprises, but also reducethe error rate of the number of bundled steel bars in finished products, whichis very conducive to the sustainable development of enterprises.

The disadvantages of traditional methods

The traditional steel bar counting method mainly relies onmanual labor, which is not only inefficient but also susceptible to humanfactors, resulting in inaccurate counting results. The drawbacks of manualcounting are mainly reflected in the following aspects:

-Efficiency issue: The manual counting speed is slow andcannot meet the needs of large-scale production.

-Accuracy issue: Manual counting is easily affected byfactors such as fatigue and distraction, leading to counting errors.

-Cost issue: With the continuous rise of labor costs,traditional manual counting methods are becoming increasingly uneconomical interms of cost.

-Safety issues: Long term manual counting work also has acertain impact on the physical health of workers.

Technical advantages

-Automated counting: Without manual intervention, theequipment automatically completes the counting of steel bars, ensuring thecontinuity and accuracy of the counting process.

-High compatibility: Suitable for steel bars of differentdiameters and types, including rebar and bars, covering mainstreamspecifications in the market.

-Easy to operate: The user interface is user-friendly andeasy to operate, even non professionals can quickly get started.

-High precision recognition: Using deep learningalgorithms, the accuracy of steel bar counting can reach ï 2 , far higher thantraditional manual counting methods.

-Real time feedback: The device can provide real-timefeedback on the counting results. Once an error is detected, it willimmediately alert the user through a light alarm to ensure timely correction.

-Intelligent Correction: Supports manual correctionfunction, allowing users to fine tune the counting results according to actualsituations, further improving the accuracy of counting.

-Environmental adaptability: It can maintain high accuracyin counting even in complex environments such as low light or overlapping steelbars, demonstrating excellent environmental adaptability.

Through these technological advantages, the whole bundlesteel bar counter not only improves the efficiency of steel bar counting, butalso saves a lot of labor costs for enterprises, making it an indispensableintelligent device in the construction industry.

Other Products in 'C and O2 Control and Sampling System' category

|

ANSSEN METALLURGY GROUP CO.,LTD

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry